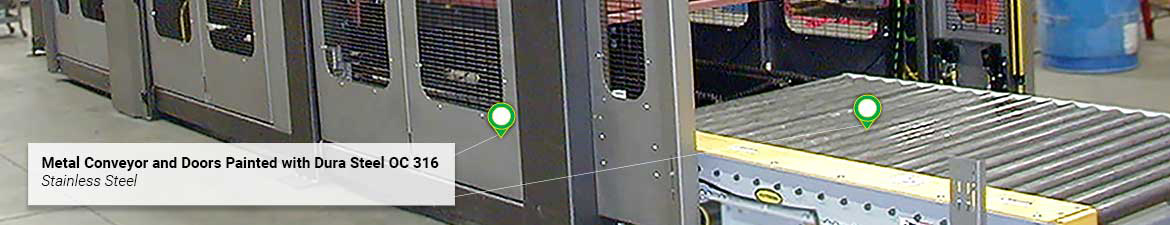

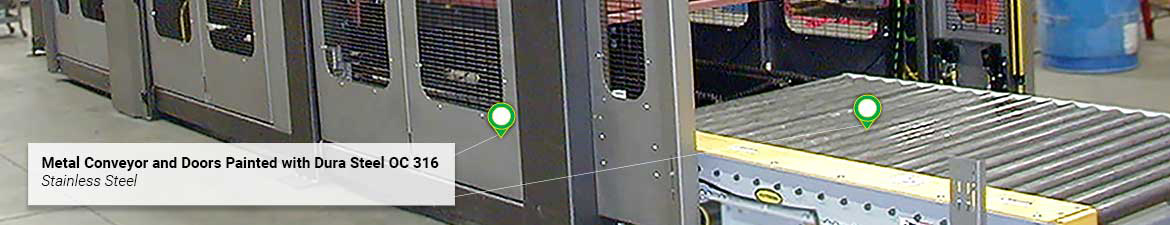

Gray Metal Primer Coating Stainless Steel Water-Based Epoxy Dura-Steel OC 316™

Dura-Steel O.C. 316™ is a water-based epoxy stainless steel metal primer where long-term protection is needed. Formulated 316 stainless steel flake, this epoxy primer is zinc free, low VOC, HAPS-free and is chip resistant. Our Liquid Stainless Steel Primer for Metal is a two-component system.

- Description

- Request Best Price - Information

- Dura-Steel OC 316 Physical Properties

- Additional information

Stainless Steel Gray Water-Based Epoxy Metal Primer Coating

Dura-Steel 316™ OC is different in that it is a one coat product that both primes and finishes in a one coat application and yet offers the corrosion protection of most two-coat systems. Dura-Steel 316 OC passes ASTM B-117 salt spray testing for 1000 hours. While Dura-Steel 316 OC can be used directly to the metal in a one coat application, it also works extremely well as a primer for all of our stainless and non-stainless topcoats.

Dura Steel OC 316 water-based two-party epoxy metal primer is a heavy duty metal epoxy primer/finish for use on the metal where maximum long-term protection is desired. It’s a zinc free, chip resistant formula, reinforced with 316 stainless steel flake. The VOC is under 110 g/l to comply with stricter VOC standards and is HAPS free.

How to Apply Metal Epoxy Metallic Stainless Steel Primer:

Only Apply Dura-Steel OC 316™ when air and surface temperatures are between 50oF and 100oF and surface temperature is at least 5oF above the dew point.

Preparing the Metal Surface for Epoxy Primer Coating:

Remove all dirt, grease, oil, salt, and chemical contaminants by washing the surface with BC-4000 cleaner or other suitable cleaners. Thoroughly cured old coatings or new smooth metal may require scuff sanding for maximum adhesion. Aluminum surfaces should be washed with BC7000 and rinsed with clean water prior to applying stainless steel epoxy metal primer - finisher.

Mixing: 3 to 1 mix water-based epoxy gray stainless steel primer for metal

For Moderate Exposure Metal: Abrasive blast to SSPC-SP-6 commercial blast before priming.

For Severe Exposure Metal: An abrasive blast to SSPC-SP-10 near white blast before priming.

Required Curing Agent: 16-500B; mixing ratio (3) parts “A” + (1) part “B” by volume

Epoxy Metal Stainless Steel Metal Primer Finisher Appearance: Metallic Satin Gray

Recommended Topcoats: For maximum protection, a coat of Steel Plus CE Series Epoxy Topcoats can be used over Dura Steel OC

How to Thin Water-Based Epoxy Stainless Steel Metal Primer - Finisher:

Using a Roller or Brush: Use as mixed. Dilute with water as needed.

Using an Air Atomizer Sprayer: Dilute 5-10% with water if needed.

Using an Airless Sprayer: Normally use, dilution not needed.

Dura-Steel OC 316™ Cleanup Soap and Water

Recommended Equipment for Dura-Steel OC 316™ Coating:

Filter: Use nylon bag when needed:

Brush: Use a quality synthetic bristle brush

Roller: Use quality roller cover

Air Atomized Spraying: Follow equipment manufacturer’s nozzle and needle selection recommendation for use with medium viscosity paints. Spray at 45-60 psi.

Airless Spraying: 1800-2400 psi with 0.015 to 0.019 tip.

Dura-Steel OC 316™ Specifications:

When Part "A" and Part "B" Are mixed:

Weight Per Gallon: 9.62 Lbs

Solids by Weight: 41.97%

Solids by Volume: 36.16% (part “A” alone), 34.55% (part “A” & “B” combined)

Recommended: DFT: 2.5 mils

WFT to Achieve: DFT 7.3 mils

Induction Time: None

Theoretical Coverage: @1 MIL DFT 553 sq. ft./gal

Actual Coverage at Recommended DFT: 221 sq. ft./gal

Dry Time @77F and 50% Humidity:

Tack Free: 60 minutes

Handle: 2-4 hour

Recoat: 1 hour after dry to touch

Full Cure: 7 days (drying can be accelerated)

Pot Life: 2 hours (mix just enough paint to use up in 2 hours)

Heat Resistance When Fully Cured: 300F

Shelf-Life: 2 years

Safety Information for Metal Epoxy Stainless Steel Primer:

VOC: 109 g/L or 0.91 Lb/gal (parts “A” & “B” combined)

Flash Point: N/A

California Prop. 65 warning: Detectable amounts of chemicals known to the state of California to cause cancer, birth defects or other reproductive harm, may be found in this product or its vapors. For specific information refer to the Safety Data Sheet(SDS)

*** FOR INDUSTRIAL USE ONLY. KEEP OUT OF REACH OF CHILDREN. ***

Dura-Steel OC 316™ Ordering Information:

| Product Number | Size | Wt./Case | Case Quantity |

| 10-216A-F4 | 1 Quart | 27 | 6 |

| 10-216A-F1 | 1 Gallon | 37 | 4 |

| 10-216A-F5 | 5 Gallon | 49 | 1 |

DuraSteel OC316™ Stainless Steel Look Metal Primer Coating Requires Curing Agent 16-500B

Stainless Steel Gray Water-Based Epoxy Metal Primer Coating Dura-Steel 316™ O.C. |

WEIGHT PER GALLON 9.62 Lbs

SOLIDS BY WEIGHT 41.97%

SOLIDS BY VOLUME 36.16% (part “A” alone), 34.55% (part “A” & “B” combined)

RECOMMENDED DFT 2.5 mils

WFT TO ACHIEVE DFT 7.3 mils

INDUCTION TIME None

THEORETICAL COVERAGE @1 MIL DFT 553 sq. ft./gal

ACTUAL COVERAGE AT RECOMMENDED DFT 221 sq. ft./gal

DRY TIME @77OF

AND 50% HUMIDITY Tack Free: 60 minutes

Handle: 2-4 hour

Recoat: 1 hour after dry to touch

Full Cure: 7 days (drying can be accelerated)

POT-LIFE 2 hours (mix just enough paint to use up in 2 hours)

HEAT RESISTANCE

OF CURED FILM 300oF

SHELF-LIFE 2 years

Additional information

| Size | Quart, Gallon, 5 Gallons |

|---|

Stainless Steel Gray Water-Based Epoxy Metal Primer Coating

Dura-Steel 316™ OC is different in that it is a one coat product that both primes and finishes in a one coat application and yet offers the corrosion protection of most two-coat systems. Dura-Steel 316 OC passes ASTM B-117 salt spray testing for 1000 hours. While Dura-Steel 316 OC can be used directly to the metal in a one coat application, it also works extremely well as a primer for all of our stainless and non-stainless topcoats.

Dura Steel OC 316 water-based two-party epoxy metal primer is a heavy duty metal epoxy primer/finish for use on the metal where maximum long-term protection is desired. It’s a zinc free, chip resistant formula, reinforced with 316 stainless steel flake. The VOC is under 110 g/l to comply with stricter VOC standards and is HAPS free.

How to Apply Metal Epoxy Metallic Stainless Steel Primer:

Only Apply Dura-Steel OC 316™ when air and surface temperatures are between 50oF and 100oF and surface temperature is at least 5oF above the dew point.

Preparing the Metal Surface for Epoxy Primer Coating:

Remove all dirt, grease, oil, salt, and chemical contaminants by washing the surface with BC-4000 cleaner or other suitable cleaners. Thoroughly cured old coatings or new smooth metal may require scuff sanding for maximum adhesion. Aluminum surfaces should be washed with BC7000 and rinsed with clean water prior to applying stainless steel epoxy metal primer – finisher.

Mixing: 3 to 1 mix water-based epoxy gray stainless steel primer for metal

For Moderate Exposure Metal: Abrasive blast to SSPC-SP-6 commercial blast before priming.

For Severe Exposure Metal: An abrasive blast to SSPC-SP-10 near white blast before priming.

Required Curing Agent: 16-500B; mixing ratio (3) parts “A” + (1) part “B” by volume

Epoxy Metal Stainless Steel Metal Primer Finisher Appearance: Metallic Satin Gray

Recommended Topcoats: For maximum protection, a coat of Steel Plus CE Series Epoxy Topcoats can be used over Dura Steel OC

How to Thin Water-Based Epoxy Stainless Steel Metal Primer – Finisher:

Using a Roller or Brush: Use as mixed. Dilute with water as needed.

Using an Air Atomizer Sprayer: Dilute 5-10% with water if needed.

Using an Airless Sprayer: Normally use, dilution not needed.

Dura-Steel OC 316™ Cleanup Soap and Water

Recommended Equipment for Dura-Steel OC 316™ Coating:

Filter: Use nylon bag when needed:

Brush: Use a quality synthetic bristle brush

Roller: Use quality roller cover

Air Atomized Spraying: Follow equipment manufacturer’s nozzle and needle selection recommendation for use with medium viscosity paints. Spray at 45-60 psi.

Airless Spraying: 1800-2400 psi with 0.015 to 0.019 tip.

Dura-Steel OC 316™ Specifications:

When Part “A” and Part “B” Are mixed:

Weight Per Gallon: 9.62 Lbs

Solids by Weight: 41.97%

Solids by Volume: 36.16% (part “A” alone), 34.55% (part “A” & “B” combined)

Recommended: DFT: 2.5 mils

WFT to Achieve: DFT 7.3 mils

Induction Time: None

Theoretical Coverage: @1 MIL DFT 553 sq. ft./gal

Actual Coverage at Recommended DFT: 221 sq. ft./gal

Dry Time @77F and 50% Humidity:

Tack Free: 60 minutes

Handle: 2-4 hour

Recoat: 1 hour after dry to touch

Full Cure: 7 days (drying can be accelerated)

Pot Life: 2 hours (mix just enough paint to use up in 2 hours)

Heat Resistance When Fully Cured: 300F

Shelf-Life: 2 years

Safety Information for Metal Epoxy Stainless Steel Primer:

VOC: 109 g/L or 0.91 Lb/gal (parts “A” & “B” combined)

Flash Point: N/A

California Prop. 65 warning: Detectable amounts of chemicals known to the state of California to cause cancer, birth defects or other reproductive harm, may be found in this product or its vapors. For specific information refer to the Safety Data Sheet(SDS)

*** FOR INDUSTRIAL USE ONLY. KEEP OUT OF REACH OF CHILDREN. ***

Dura-Steel OC 316™ Ordering Information:

| Product Number | Size | Wt./Case | Case Quantity |

| 10-216A-F4 | 1 Quart | 27 | 6 |

| 10-216A-F1 | 1 Gallon | 37 | 4 |

| 10-216A-F5 | 5 Gallon | 49 | 1 |

DuraSteel OC316™ Stainless Steel Look Metal Primer Coating Requires Curing Agent 16-500B