Corrosion Resistant Single Component Metal Primer PrimeLock™

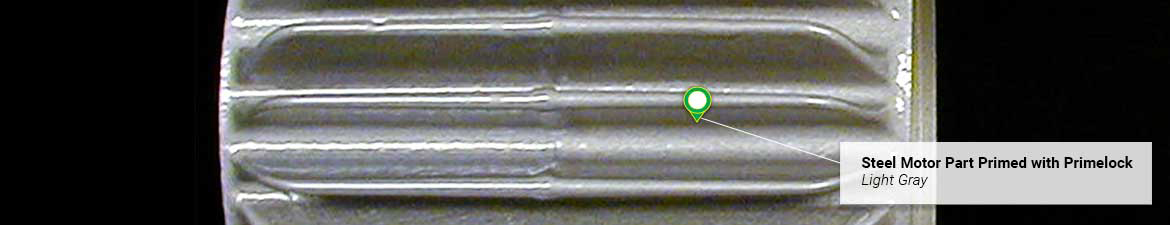

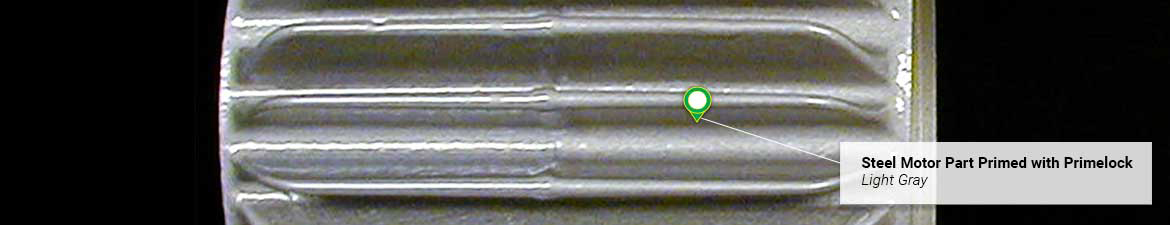

PrimLock is a water-based, low VOC, single component, rust inhibitive acrylic primer. With a gray finish, this metal primer renders excellent water-resistance and corrosion-resistance for most metal surfaces.

[vc_row][vc_column][vc_column_text]

Single Component Metal Primer PrimeLock™ 7169

Prime Lock Low VOC Primer is a single component acrylic with a VOC under 100 grams per liter. It is our most corrosion resistant single component primer. Excellent for exterior and interior applications in mild to moderate corrosive environments. Prime Lock passes ASTM B-117 to 1000 hours, virtually unheard of for any single component water based primer. It can be used under any of our single component topcoats. Available in Light Gray[/vc_column_text][vc_column_text]

How to Apply Single Component Acrylic Metal Primer:

Surface Preparation:

Remove all dirt, grease, oil, salt and chemical contaminants by washing the surface with BC-4000 cleaner or other suitable cleaners. Thoroughly cured old coatings or new smooth metal may require scuff sanding for maximum adhesion.

Moderate Exposure: Abrasive blast to SSPC-SP-6 commercial blast before priming.

Severe Exposures: an Abrasive blast to SSPC-SP-10 near white blast before priming.

Acrylic Metal Primer Application Temperatures:

How to Thin Acrylic Metal Primer:

Only apply metal primer when air and surface temperatures are between 50oF and 100oF and surface temperature is at least 5oF above the dew point.

Roller or Brush Primer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Air Atomizing Praying Primer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Airless Spraying Primer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

CleanUp:

Soap and water

Recommended TopCoats: Superlife 316 Low VOC, Steel Tuff 316, Topcoat 1010, Steel Plus Epoxy Topcoats[/vc_column_text][vc_column_text]

Equipment Recommended applying Metal Primer PrimeLock 7169:

Filter: Use 100 mesh stainless steel screen or nylon bag when needed

Brush: Use a quality synthetic bristle brush

Roller: Use quality roller cover

Air Atomized Sprayer: Follow equipment manufacturer’s nozzle and needle selection recommendation for use with heavy latex paints. Spray at 45-60 psi.

Airless Sprayer: 2000-2500 psi with 0.015 to 0.019 tip.

Hot Spraying Temiture: 100-120F

PrimeLock-7169 Metal Primer VOC Information: 61.4 g/L or 0.52 Lbs/gal[/vc_column_text][vc_column_text]7169 Metal Primer Appearance: Flat Light Gray[/vc_column_text][vc_column_text]

*** FOR INDUSTRIAL USE ONLY. KEEP OUT OF REACH OF CHILDREN. ***

PrimeLock 7169 Metal Acrylic Primer Ordering Information:

| Product Number | Size | Wt./Case | Case Quantity |

| 30-7169-01 | Gallon | 44 | 4 |

| 30-7169-05 | 5 Gallons | 58 | 1 |

| 30-7169-55 | 55 Gallons | 610 | 1 |

[/vc_column_text][/vc_column][/vc_row]

WEIGHT PER GALLON 11.39 Lbs

SOLIDS BY WEIGHT 56.3%

SOLIDS BY VOLUME 40.3%

RECOMMENDED DFT 2.5 mils

WFT TO ACHIEVE DFT 6.5 mils

THEORETICAL COVERAGE @1 MIL DFT 644 sq. ft./gal

ACTUAL COVERAGE AT RECOMMENDED DFT 258 sq. ft./gal

DRY TIME @77OF AND 50% HUMIDITY Tack Free: 15-30 minutes

Handle: 1-2 hour

Recoat: 4-6 hours

Full Cure: 7 days (can be accelerated)

HEAT RESISTANCE OF DRIED FILM 350oF

SHELF-LIFE 2 year

PACKAGING 1 gallon, 5 gallons, and 55-gallon drum

Additional information

| Size | Gallon, 5 Gallon, 55 Gallon |

|---|

Single Component Metal Primer PrimeLock™ 7169

Prime Lock Low VOC Primer is a single component acrylic with a VOC under 100 grams per liter. It is our most corrosion resistant single component primer. Excellent for exterior and interior applications in mild to moderate corrosive environments. Prime Lock passes ASTM B-117 to 1000 hours, virtually unheard of for any single component water based primer. It can be used under any of our single component topcoats. Available in Light Gray[/vc_column_text][vc_column_text]

How to Apply Single Component Acrylic Metal Primer:

Surface Preparation:

Remove all dirt, grease, oil, salt and chemical contaminants by washing the surface with BC-4000 cleaner or other suitable cleaners. Thoroughly cured old coatings or new smooth metal may require scuff sanding for maximum adhesion.

Moderate Exposure: Abrasive blast to SSPC-SP-6 commercial blast before priming.

Severe Exposures: an Abrasive blast to SSPC-SP-10 near white blast before priming.

Acrylic Metal Primer Application Temperatures:

How to Thin Acrylic Metal Primer:

Only apply metal primer when air and surface temperatures are between 50oF and 100oF and surface temperature is at least 5oF above the dew point.

Roller or Brush Primer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Air Atomizing Praying Primer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

Airless Spraying Primer: Use clean water. Thinning is normally not required. Use 5%-10% if needed (approximately 1/2 pint per gallon)

CleanUp:

Soap and water

Recommended TopCoats: Superlife 316 Low VOC, Steel Tuff 316, Topcoat 1010, Steel Plus Epoxy Topcoats

Equipment Recommended applying Metal Primer PrimeLock 7169:

Filter: Use 100 mesh stainless steel screen or nylon bag when needed

Brush: Use a quality synthetic bristle brush

Roller: Use quality roller cover

Air Atomized Sprayer: Follow equipment manufacturer’s nozzle and needle selection recommendation for use with heavy latex paints. Spray at 45-60 psi.

Airless Sprayer: 2000-2500 psi with 0.015 to 0.019 tip.

Hot Spraying Temiture: 100-120F

PrimeLock-7169 Metal Primer VOC Information: 61.4 g/L or 0.52 Lbs/gal

7169 Metal Primer Appearance: Flat Light Gray

*** FOR INDUSTRIAL USE ONLY. KEEP OUT OF REACH OF CHILDREN. ***

PrimeLock 7169 Metal Acrylic Primer Ordering Information:

| Product Number | Size | Wt./Case | Case Quantity |

| 30-7169-01 | Gallon | 44 | 4 |

| 30-7169-05 | 5 Gallons | 58 | 1 |

| 30-7169-55 | 55 Gallons | 610 | 1 |